Robotic Process Automation

Custom Warehouse and Factory Robot

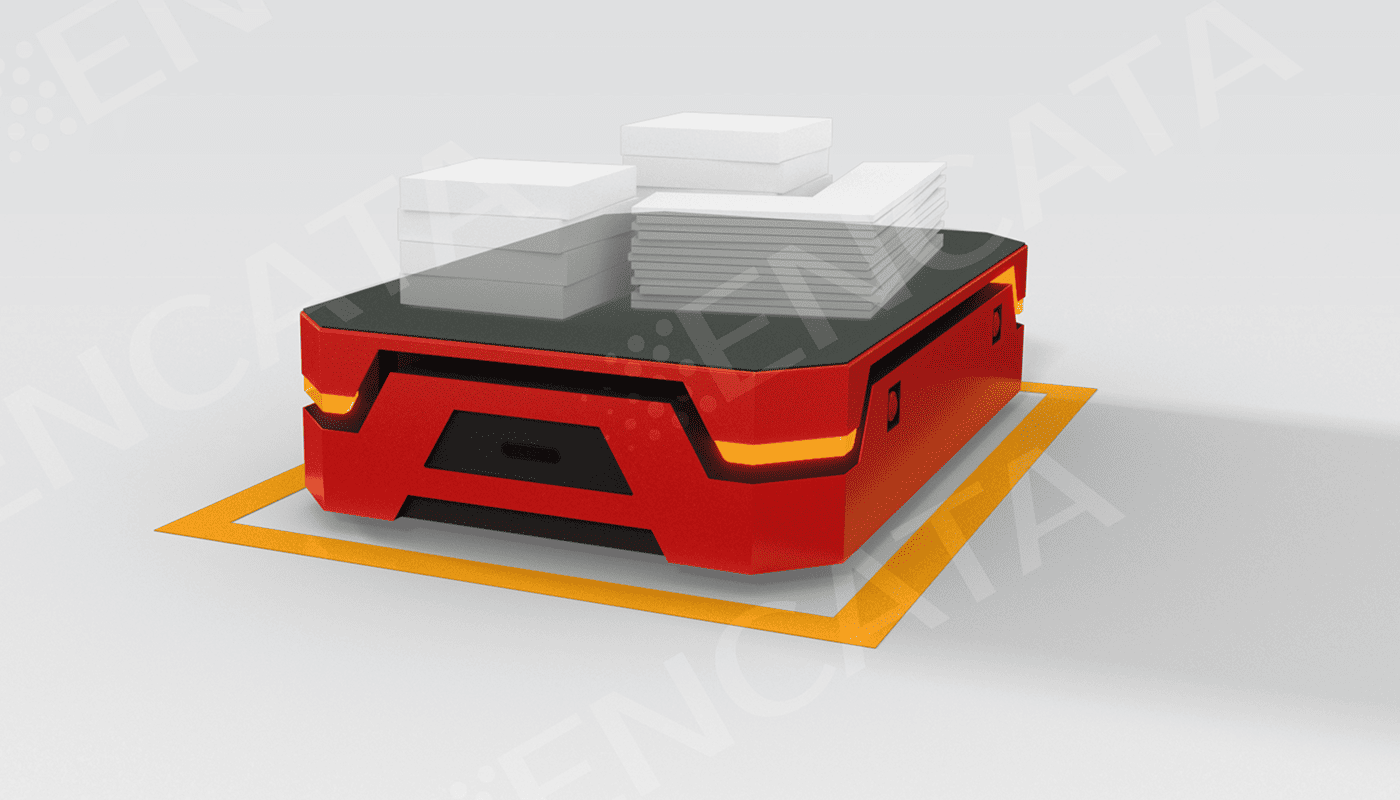

EnCata developed a minimum viable product – a robot for factory and warehouse automation. It can carry loads of up to 200 kg, operate autonomously for 3 hours without recharging, and features a 120×80×40 cm platform.

What was the main challenge in this project?

The client, a startup in the automation field, needed to create a reliable autonomous carrier robot (MVP) to optimize material handling processes in a production environment. The primary challenge was developing a safe, high-performance solution that could integrate into a dynamic factory floor and be designed for future serial production. The robot had to feature high load capacity and extended autonomy.

What was your solution or approach?

We executed the full development cycle, focusing on Design for Manufacturing (DFM), electronic safety, and component unification.

- Mechanics and Design: The structure was optimized for standard manufacturing processes—laser cutting, bending, and welding—which minimized the cost and time of the MVP phase.

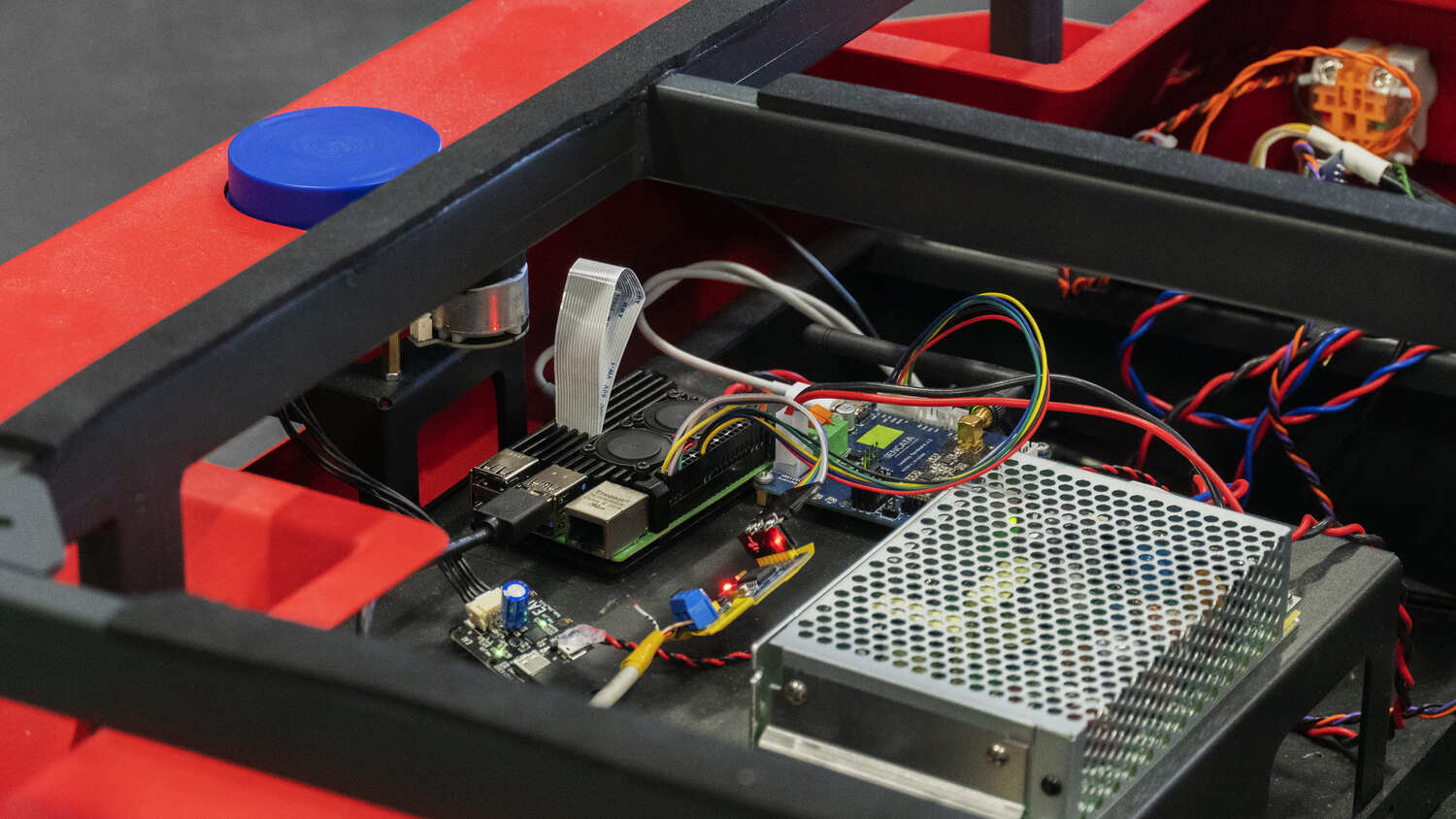

- Electronics and Safety: To ensure the reliable operation of the powerful drives, we developed a custom power distribution board with a resistor-relay "soft start" scheme to prevent overloads and arcing. We also implemented a hardware-level power cut-off for maximum safety.

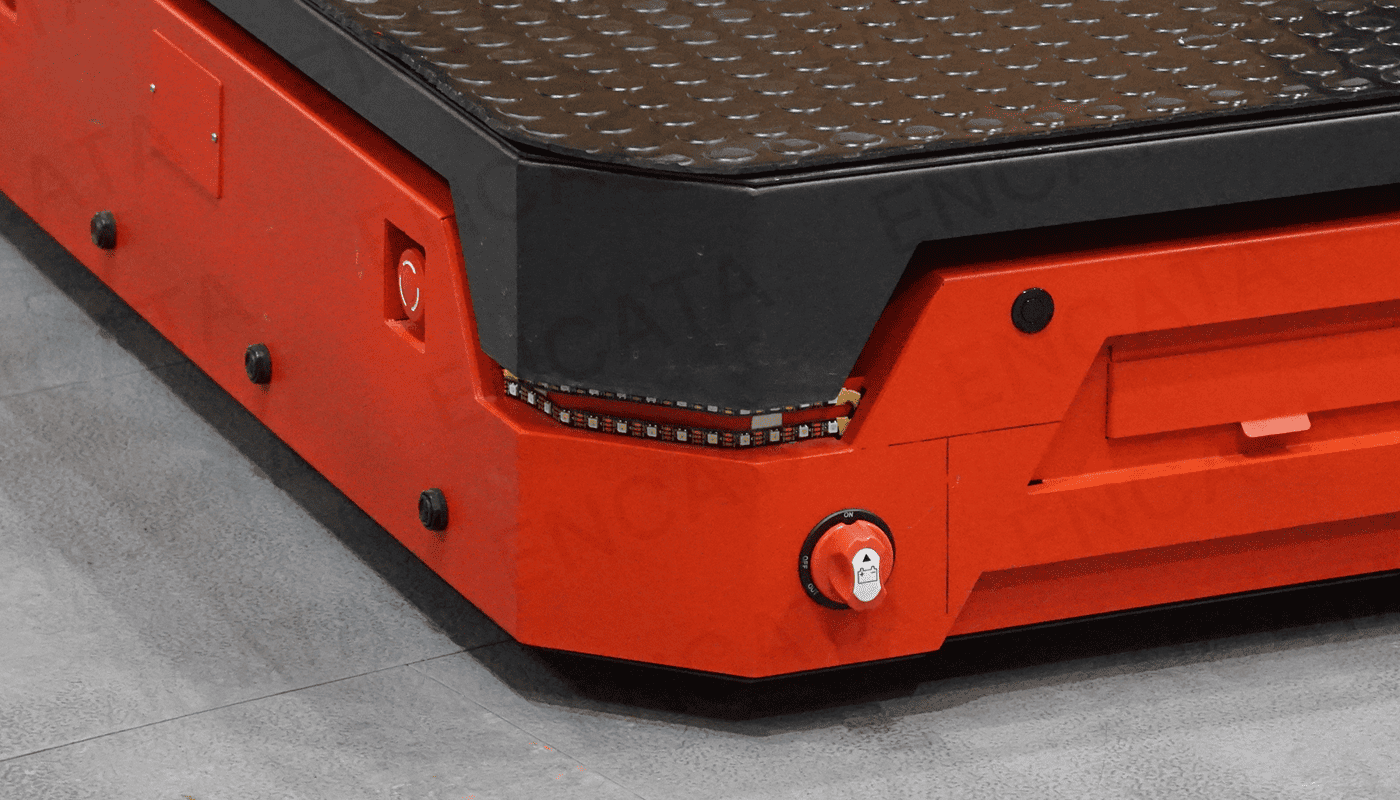

- Unification: To simplify assembly and maintenance, we created a universal sensor and indicator board. Using a hardware decoder, the same board and firmware version perform different functions on each of the robot's four sides.

What was the outcome or impact for the client?

The 12-month project resulted in the development and manufacturing of the first iterative prototype of the LeanKey robot, which was successfully tested in a production environment. The client received an industrial-ready MVP that proved the technical feasibility of a complex autonomous system.

The robot offers a load capacity of 200 kg, provides up to 3 hours of autonomous operation under load, and reaches a maximum speed of 0.5 m/s. It can autonomously navigate pre-set routes, build maps (SLAM), and dynamically avoid obstacles, confirming its readiness for scaling and integration into logistics workflows.

Other case studies from EnCata Product Development

Other robotic process automation case studies

Robotic Process Automation

Project Details

E

Duration:6 - 12 months

Project URLSTM32Wi-FiBLEFreeRTOSVision and detection systemVacuum formingWeldingLaser cuttingROS2Raspberry Pi 4

Need similar services?

Agencies providing robotic process automation

Posted this

E

EnCata is an end-to-end service & solutions provider for IoT, robotics, hardware, R&D and manufacturing

Q

E

Digitize your business with an IT solutions partner.

T

Transforming Digital Excellence through Innovation and Performance

R

Sparking Innovation, Yielding Outcomes

L

Transforming Visions into Digital Reality

T

Building relationships and delivering powerful online solutions

4

Adopt, Automate, Transform with Data-Driven Digital Solutions 🚀

K

Driving businesses ahead of the competition with digital excellence

D

Transforming Businesses with Artificial Intelligence 💻