Mobile App Development

SRMG Verify Mobile Application

SRMG Verify is used to track and report on the pickup, delivery activity and accuracy of SRMG products to its customers. When the SRMG shipment arrives at any customer destination, the receiver performs a delivery scan. The scan provides SRMG with the data to track and evaluate accuracy of deliveries so as to make corrections on invoicing and also on future shipments to SRMG customers. The process gives the customer the ability to see the shipping status of their expected delivery at any moment in time.

The primary goal of this project was to create a shipment tracking application for both iOS and Android that utilizes barcode scanning, real-time geolocation, real-time shipment updates, offline shipment scanning support, and is fully integrated with SRMG’s internal Command system for shipment reconciliation.

What was the main challenge in this project?

Bar Code Scanning

SRMG needed the ability to scan any barcode with the users mobile phone. Upon each scan, the user would need to presented with the shipment details, as well as provide inputs to complete the shipment details of full loads, partial loads, and load quantities. Users also needed to be able to enter the barcodes manually or with voice activation inputs in case of damaged or unreadable bars.

Realtime Geo-Location (Shipment Status)

SRMG presented a unique challenge around geolocation. The requirement is such that when a user logs into the application and checked the status of shipments (in route or by material etc), the users real-time geolocation would need to be used to show only shipment status at the particular facility location of the app user. Geolocation radius constraints would need to be set within the app to ensure that shipments statuses for close proximity facilities were not shown incorrectly.

SRMG Order Management System Integration

The app would need to integrate and send data back and forth/synchronize with SRMG’s internal order management system in near real time and follow a set of data processing rules to ensure data accuracy and integrity.

What was your solution or approach?

Since SRMG started at only the concept level with limited requirement assets, we took a full end to end service approach. We started with a strategic planning phase conducting multiple discovery and planning workshops to obtain the business analysis, application requirements and other mission critical definition. We then proceeded to a design and non functional rapid prototyping phase that provided the stakeholders with a predevelopment snapshot of what will look like and a sense of how it would function. the app will be. Once approved by SRMG we then moved into alpha development and QA and delivered each iteration to teh SRMG staff. at the conclusion of Alpha development we moved to Beta testing and bug fixing until we had a well tested deployable solution.

Strategic planning workshops

UX /UI Design

Rapid Prototyping

Iterative Development

API integration

Alpha testing and QA

Client UAT internal beta testing

Client UAT closed group beta testing

Product knowledge transfer and training

Marketplace publishing

Continued warranty support and maintenance

What was the outcome or impact for the client?

The outcome of this project produced Android and iOS mobile applications exclusive to Salt River Materials Group. The SRMG Verify mobile apps give the Batch Plant Coordinators the ability to track shipments in transit and scan shipments as they are received in real time. The mobile apps also give the SRMG Shipping / Order Managers the ability to process orders on the way out the door more efficiently, manage order problems, and reconcile both diverted and split loads more effectively.

Other case studies from Dot Com Development

Web & Software Development

PeakLoad Web Application

Web & Software Development

PathMaker Web Application

Web & Software Development

momAgenda Web Application

Web & Software Development

Elevation Marketing Lead Generation Website

Mobile App Development

Legacy Stay Present Mobile Application

Mobile App Development

Doc Talk® Mobile Application

Other mobile app development case studies

Mobile App Development

Mobile App Development

KKodexo Labs

Wattba – Smart Appointment Management Solution

DesignMobile DevelopmentQA and Testing

Mobile App Development

KKodexo Labs

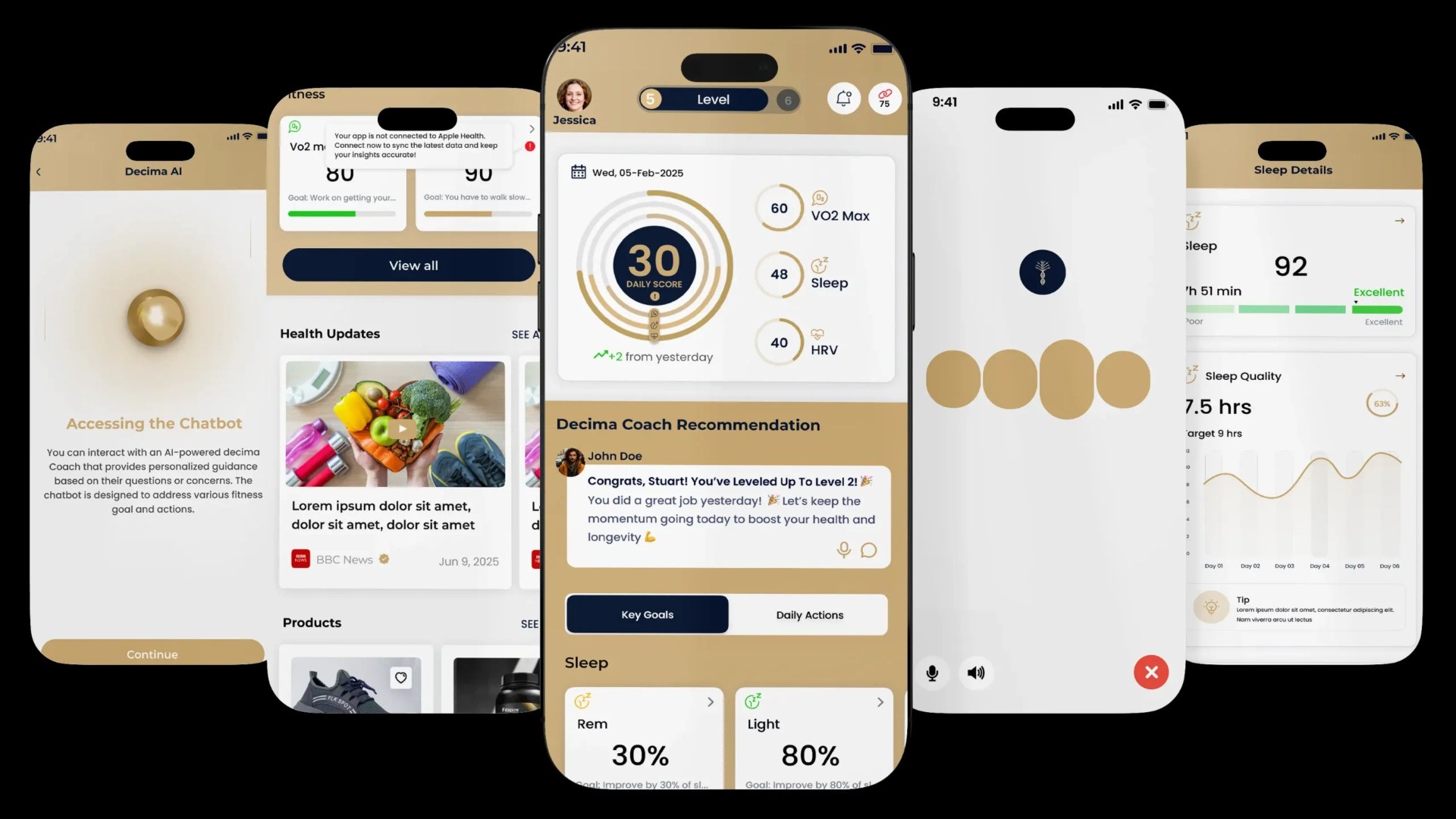

Decima | AI-Powered Health Coaching Platform

Mobile App DevelopmentSoftware DevelopmentAI Development+2

Mobile App Development

Mobile App Development

Mobile App Development

CCassovia Code

Development of a SMART App for Performing Car Inspections

ReactReact NativePHP

Project Details

Need similar services?

Agencies providing mobile app development

Posted this

D

k

KD Software Pvt Ltd is a Leading Website Designing company in bengaluru, Greater bengaluru.

4

Designing and Developing Digital Solutions for Brands

Q

Increasing Business Success with Quality Solutions

C

Establishing online presence through innovative digital solutions.

N

Transforming Digital Experience Across Industries

Y

A Trusted Software Development Company in the USA for Scalable Digital Growth

A

Customized software development solutions for a digital world.

N

F

Building digital experiences that engage and convert

C

Your professional tech department for web and software development.